China’s Double 11 2025: Record Demand, Policy Support, and New Openings for Global eCommerce Sellers

Reading Time: 2 minutesChina’s Double 11 shopping festival — the world’s largest annual online retail…

Inventory management best practices are here to counter the chaos unleashed by poor inventory management during the holiday season rush. Here we discuss adopting smart techniques to help you make the right decision and leverage unpredictable demand ahead to your favor.

As a result, you will be able to hit the sweet spot to strike a balance between demand and supply. Moreover, you will be able to put effort into other crucial business operations without compromising.

Inventory bottleneck might result in severe consequences like overselling, underselling, delay in shipping, and more. Repercussions might be different, but the impact will be the same. You will lose loads of sales opportunities to your competitors.

With the festive season fast approaching, the opportunities lost will be maximum. But it isn’t a big reason to panic. After all, the post discusses in detail what helps to manage the inventory like a pro.

The problem of low stocks due to overselling during the holiday season is not unusual. The Just In Time inventory approach is an effective technique provided you did enough in-depth research on customer buying patterns and are confident about what is likely to be next in their shopping list. Then you stock inventory only in a quantity that will soon sell. Hence one among the trusted inventory management best practices best suited for experienced merchants.

It is a unique code that helps in product tracking thereby making inventory management easy and quick.

Image credit: Corporate Finance Institute

Assigning SKU to every item will benefit in the below manner

Suppose you provide an offer on the purchase of 2 or more products during the holiday season. Now, assigning SKU to bundled products will help in tracking those products. Moreover, you will also be able to separately track individual items in the package on the bright side. Yes, SKU is crucial to experience smooth inventory management.

Frequent inventory stock-out situations will hamper the brand reputation. But, partnering up with suppliers/manufacturers owning warehouses equipped with a skilled workforce in huge quantities ensures you can cater to the high demand during the holiday season.

This festive season, say goodbye to poor inventory management and its repercussions by opting for the smart approach for inventory management.

In-depth analysis of previous year sales during Q4 (Oct-Dec) will reveal high demand and moderate demand products. Accordingly, replenish your stocks because sales figures always grow in respect to the previous year.

Did you know that Pandemic couldn’t completely curb the joy of shopping because 2020 holiday sales grew more than 13 percent in comparison to 2019.

Products with lucrative offers are likely to get out of stocks at a comparatively rapid pace.

Customers consider these to be hard to resist offers. If you plan to offer a similar offer, it means you have to have ample inventory readily available in the warehouse. Hence, you can easily avoid an out-of-stock situation and not end up undermining your sales.

Hence, inventory management best practices make it seamless and straightforward.

Doing competitive research will let you know which product your competitors run out of often. Ensure sufficient stock levels of those products. Then is the time for close and regular monitoring of your competitors. It will help you find out when they are running out of stocks.

So, the out-of-stock notification on other stores is the best time to list those products on your store and run ads for the same. After all, customers are on the lookout for alternatives, and with ads on Google, they will find your store. Offering even a 10 percent discount will make it a further lucrative option.

The most significant advantage is not going out of stock when most of your competitors are denying the item due to no supply. As a result, the customer will trust your store as a savior during hard times.

Yes, the holiday season is the busiest time of the year for online merchants. But stock restocking is critical to avoid inventory bottlenecks. Hence, take this responsibility on your shoulders.

After all, only you best know about high-priority products. Imagine you accept a vendor offer to stock your inventory. He will act as per his primary concern, which is highly unlikely to match your priority.

As a result, you might have to face a situation when your warehouse might not be filled with the right stocks. Hence, you end up returning it and reordering what you want.

This point is the minimum stock level set for every item in the warehouse, upon reaching which it’s time to reorder new inventory. As a result, you never have to wait for the stock to replenish and refuse customers or request them to wait for a few days.

Warehouse makes inventory management a smooth and efficient process by assisting accurate inventory tracking and practicing quality control.

But during the holiday season rush, it can be quite a challenge to keep the system in place and let things not fall apart. Hence focus on the below parameters and keep it going correctly with no misplaced products.

Keeping a warehouse close to the supplier’s manufacturing unit means you save time on item procurement due to short transit time. Hence notify about stock availability.

Another point to remember is ordering the inventory without any delay. It ensures ample time to get it organized by the staff. Hence, it will be ready to ship at the earliest.

Keeping your warehouse well organized makes it easy to navigate. It is vital for reducing the load-unload time of inventory. Therefore, keep all fast-moving items in an easy-access location and better keep slow-moving stuff behind them.

Trust only experienced staff to look after your warehouse management or ensure operations are carried out under the supervision of an experienced guy during the holiday season.

A warehouse with only beginners is more likely to spoil the show by making order processing a time-consuming process. Hence, the rapport of your business will suffer. It is though often undermined, but one of the crucial factors to look after.

Considering the demand surge during the holiday, if you plan to order 2X to 5X or even higher product volume than usual. Then inform the supplier in advance about the same in an in-depth manner.

It will save you from probable out-of-stock situations during holiday shopping. Also, nurturing relationships with frequent communication will work in favor of your business. It is essential to consider the crucial role of suppliers in ensuring timely order delivery.

Manual mode of inventory management and overlooking or delaying inventory tracking are a big no for enabling smooth order processing. Hence, avoid at all costs to ensure it doesn’t take away high sales opportunities during the holiday season.

A complete analysis of buyer’s purchase pattern broken down products wise for the past few years during the holiday season is indeed no less than a holy grail.

It helps you with the below insights (Let’s suppose your target product is X). It will help you predict is X worthy enough to be procured or can be just left out. Moreover, you can find the best and worst performers. Thus, making it easy to decode what to kept and in what amount.

It will allow you to decide the warehouse location better. After all, procuring it at a better site will significantly cut short shipping time because there isn’t any point in shipping stuff from a remote warehouse when you can have it done from a nearby one and delight the customer. Hence, it seem an inventory management best practice with no alternative.

These are the ones that have been bought even at high prices or without discount offers. Now, you have a list of products that can help you earn good ROI without waiting or investing too much in marketing campaigns. Moreover, you will have sufficient funds to scale your business to new heights.

Hence, it is obvious that guesswork or traditional approaches like spreadsheets will complicate the process, and you will eventually regret missing out on loads of sales opportunities.

These products will see a significant shift in demand because it helps make the person look presentable in online meetings and virtual celebrations. After all, pandemic induced increase in the virtual mode of accomplishing things increased dependency on video meetings.

With that said, get them in your warehouse before the price goes too high to be affordable with the holiday season nearing.

Firstly don’t procure it in a small amount and stress about running out of it. Also, on the flip side, if the stock is left and the holiday sale is over, then offering a discount will keep customers interested. After all, things that one needs (not want) are available at a discount price.

Following the footsteps of Walmart by having anticipation inventory keeps you ahead in the race. It helps you face the varying demand surge during the holiday season due to uncertainty in customer buying patterns.

Therefore, apart from all analysis and forecasting, it will help your business to have some stock for anticipation inventory to meet customer demand even during the unexpected phase. Yes, it sounds like the best fit for rescue inventory management best practices.

The best part of having anticipation inventory is that you won’t be shocked like others or regret having partly prepared for the unexpected rush of the holiday season. Remember not to overlook it over other concerns.

The Pro Tip: Despite all seems well and fine, a random physical counting (at least for most in-demand products of your store) will only add to your peace of mind. Therefore, you will have no shred of doubt before accepting orders.

Despite the holiday season rush, the approach mentioned above, strategies, and tactics lay the foundation for hassle-free inventory management. As a result, you have just the right amount of inventory in the warehouse.

Therefore, no more spoiling customer mood during holiday sales due to low stocks or no stocks.

Reading Time: 2 minutesChina’s Double 11 shopping festival — the world’s largest annual online retail…

Reading Time: 2 minutesAs the holiday season approaches, TikTok Shop has released its September 2025…

Reading Time: 3 minutesIn a continued effort to enable sellers and stimulate new product launches…

Reading Time: 2 minutesAs global trade enters a new phase of regulation and cost restructuring,…

Reading Time: 2 minutesOpenAI Turns to Amazon Web Services in $38 Billion Cloud Deal: What…

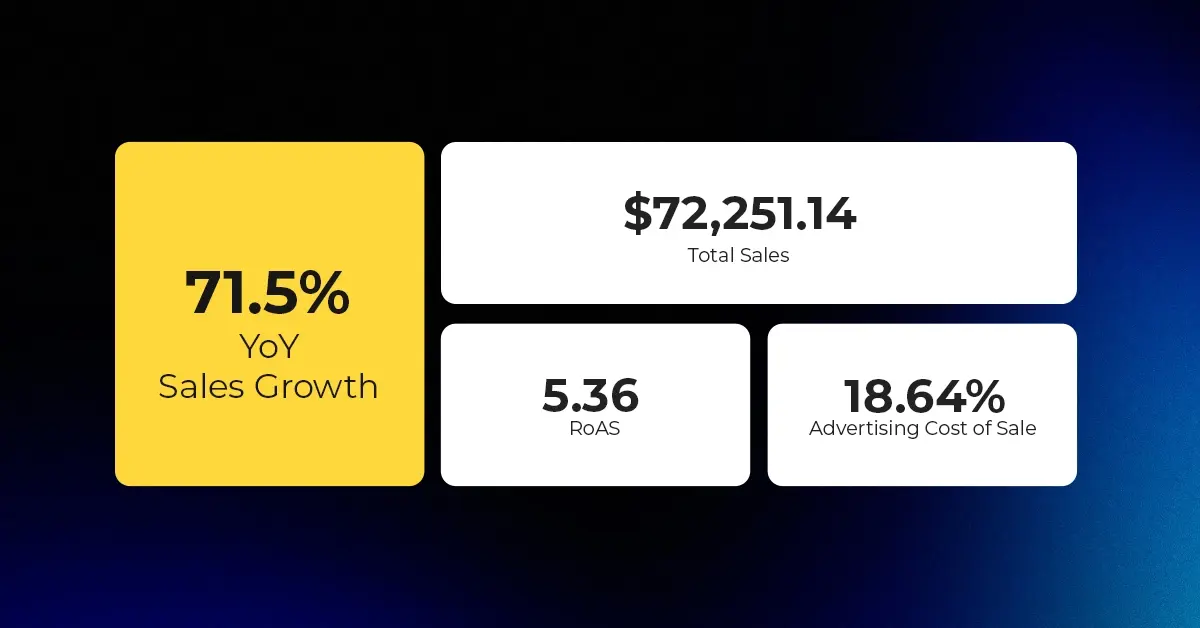

Reading Time: 4 minutesAbout the Client TMRG is a global health and wellness brand with…

Reading Time: 2 minutesAmazon Begins Quarterly Tax Reporting to China: A New Era of Cross-Border…

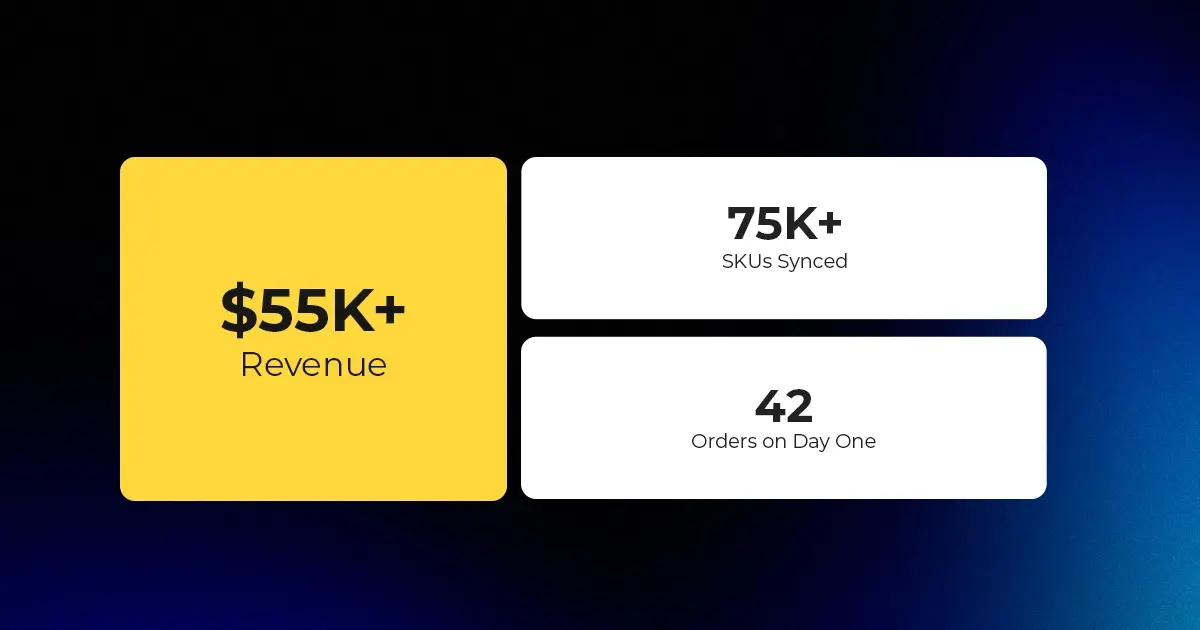

Reading Time: 2 minutesAbout the Brand Name: Stylecraft Industry: Home Décor & Lighting Location: US…

Reading Time: 2 minutesAbout the Brand Name: Flag Agency Industry: Digital Retail & Brand Management…

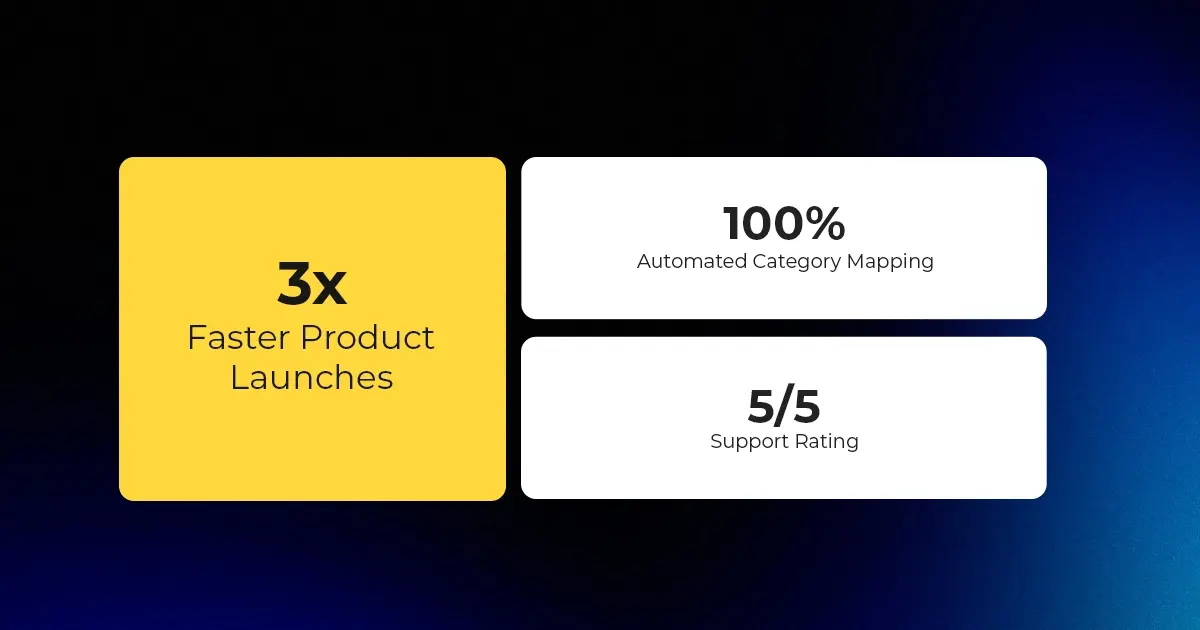

Reading Time: 2 minutesAbout the Brand Name: Stadium Goods Industry: Sneakers, Apparel & Collectibles Location:…

Reading Time: 11 minutesHalloween 2025: The Creative Seller’s Goldmine In the age of viral décor…

Reading Time: 2 minutesOverview AliExpress has launched a new global scheme — the Best Price…

Reading Time: 3 minutesEtsy, Inc. (“Etsy”) today announced two major developments: the appointment of Kruti…

Reading Time: 2 minuteseBay posted a strong performance in Q3 2025, with revenue and gross…

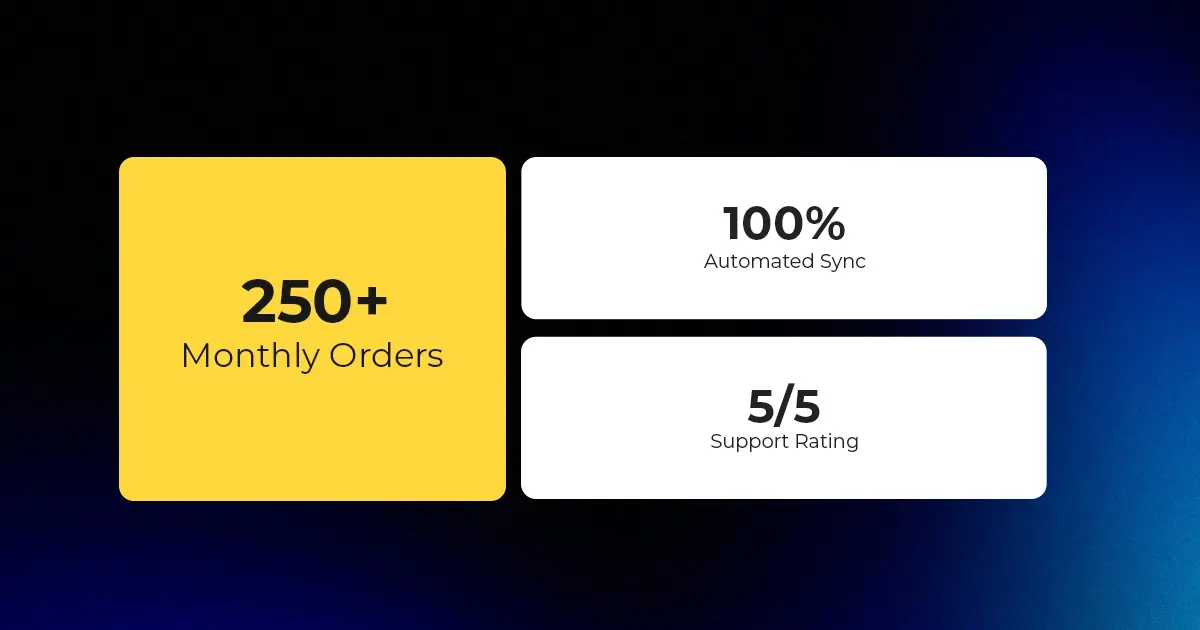

Reading Time: 3 minutesAbout the Client Esty Store: Infinite Spiral, LLC Overview: Infinite Spiral, LLC,…

Reading Time: 3 minutesWalmart has announced a landmark partnership with OpenAI that could reshape the…

Reading Time: 5 minutesAfter years of tension over the ownership and control of TikTok, the…

Reading Time: 3 minutesWalmart’s new collaboration with OpenAI signals more than a tech upgrade —…

Reading Time: 7 minutesI. INTRODUCTION: THE PRICE PRECISION IMPERATIVE In Amazon’s high-velocity marketplace, even a…

Reading Time: 3 minutesAmazon recently announced a significant change for sellers advertising in Washington state:…