Online Retail in Germany Poised for Steady Growth Through 2030, IFH KÖLN Reports

Reading Time: 3 minutesOnline retail spending in Germany is entering a renewed growth phase after…

Just ahead of Black Friday, Amazon is enforcing tighter controls on its Fulfillment by Amazon (FBA) program: sellers report reduced inbound shipment windows, SKU-level allocations (restock and inventory limits) and stricter deadline enforcement — making strategic inventory planning and backup fulfilment more critical than ever.

For holiday season cut-offs:

These changes significantly raise the stakes for Amazon sellers heading into the holiday shopping burst:

Since time is very short, here’s a tactical checklist for immediate action:

At CedCommerce, we view these changes by Amazon as a clear signal: the logistics and fulfilment ecosystem is becoming more capacity-constrained, especially ahead of peak shopping events. Sellers can no longer assume unlimited “send to FBA” space or open windows. The winners will be those who plan early, prioritise wisely and maintain operational agility.

Our key recommendations:

With only days left before the big push, every hour counts. Start executing now, monitor your metrics, and make fallback plans today. If you need help with listing optimisation, marketing, account management or expanding to other sales channels (e.g., FBM, marketplaces beyond Amazon), our CedCommerce team is ready to help.

Connect Today.

Reading Time: 3 minutesOnline retail spending in Germany is entering a renewed growth phase after…

Reading Time: 4 minutesTikTok Shop has released a comprehensive Beauty and Personal Care Products Policy,…

Reading Time: 4 minutesTikTok Shop has formally outlined comprehensive requirements for expiration date labeling and…

Reading Time: 3 minutesTikTok Shop is raising its sales commission for merchants across five active…

Reading Time: 11 minutesBy now you have seen your BFCM 2025 numbers. The harder question…

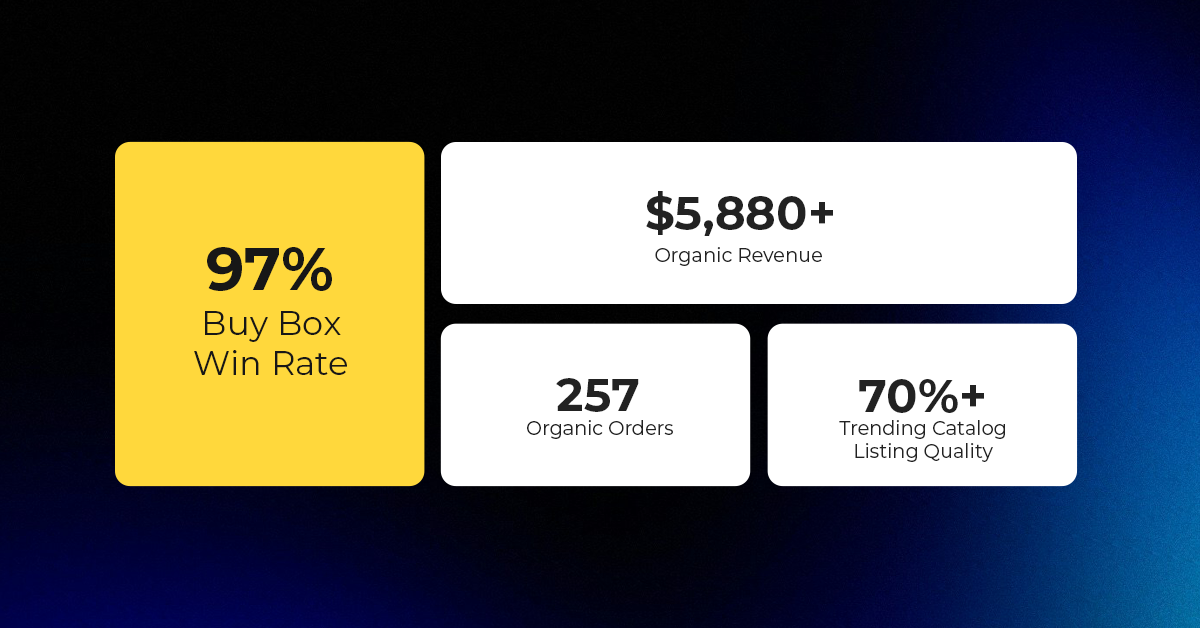

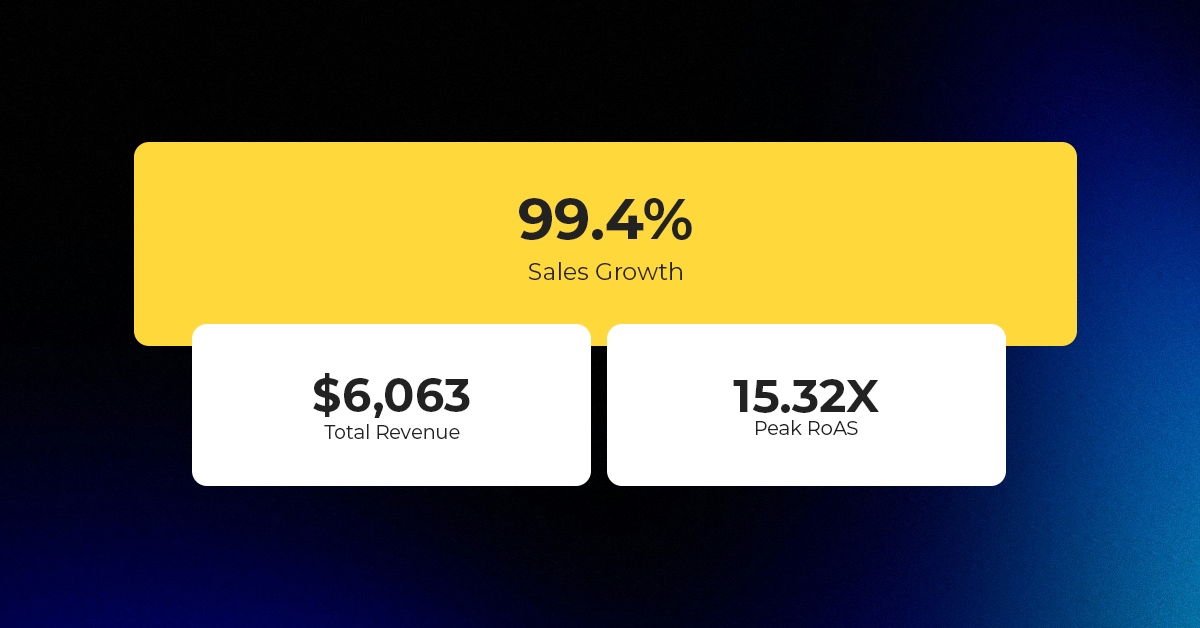

Reading Time: 3 minutesAbout the Brand Name: Vanity Slabs Inc Industry: Trading Slabs- Vanity Slabs…

Reading Time: 2 minutesAbout the Brand Name: Ramjet.com Industry: Automotive Parts & Accessories Location: United…

Reading Time: 2 minutesAmazon is rolling out strategic referral fee reductions across five major European…

Reading Time: 4 minutesQuick Summary: Scaling Lifestyle Powersports on eBay with CedCommerce Challenge: Zero marketplace…

Reading Time: 4 minutesTikTok has surpassed 460 million users across Southeast Asia, reinforcing its position…

Reading Time: 3 minuteseBay has released its final seller news update for 2025, with a…

Reading Time: 3 minutesAmazon has clarified its stance regarding speculation around a potential breakup between…

Reading Time: 4 minutesWalmart is accelerating its push into next-generation fulfillment by expanding its drone…

Reading Time: 4 minutesFaire, the fast-growing wholesale marketplace connecting independent retailers with emerging brands, has…

Reading Time: 4 minutesB2B buying in the United States is undergoing a fundamental behavioral shift…

Reading Time: 3 minutesSummary Cyber Monday 2025 has officially become the largest online shopping day…

Reading Time: 2 minutesSummary Amazon kicked off December with two major developments shaping the future…

Reading Time: 2 minutesSummary Walmart has entered December with two major moves that signal a…

Reading Time: 2 minutesBlack Friday 2025 delivered the strongest U.S. eCommerce performance in history, as…

Reading Time: 13 minutesStill approaching BFCM with generic discounts, last-minute price cuts, or scattered promotions?…